Technical Information

For additional technical support call 909.390.1905 or email us.

Product Guides

Bead Lock Mounting Instructions

WARNING: MOUNTING OF TIRES ON WHEELS CAN BE DANGEROUS IF DONE IMPROPERLY. ONLY TRAINED PERSONNEL, USING THE PROPER TOOLS, SAFETY EQUIPMENT, AND SAFETY PRECAUTIONS, SHOULD ATTEMPT TO MOUNT TIRE AND WHEEL ASSEMBLIES.

- Tires should only be mounted according to good tire mounting practices using acceptable tire mounting equipment designed for the tire industry.

- Remove the outer bead lock ring from the wheel.

- Apply tire lube on one side of the tire bead (opposite side of bead lock) and start mounting from the bead lock side.

- Once the tire is on the wheel, place the outer clamping ring onto the tire and align the bolt holes to the threaded holes in the wheel. The tire upper bead should now be sandwiched between the clamp ring and the flat base of the bead mounting surface.

- All bolts should be started by hand to avoid cross threading. Do not use Impact wrenches or air guns at any point during installation of the bead lock ring due to the possibility of over or under tightening the bolts.

- Tighten the bolts in a crisscross pattern, a few turns at a time, to ensure even pressure on the bead lock ring.

- Continuing in a crisscross pattern, tighten the bolts to the following torque specs: 4-6 ft/lbs. Check to ensure the tire is still centered on the wheel. Continue to tighten in a crisscross pattern until all bolts are torqued to 10-12 ft/lbs.

- Inflate the tire to seat the inner bead (opposite side of bead lock) onto the wheel. Do not exceed the tire manufacturer recommended maximum pressure for seating the beads.

CATASTROPHIC INJURY IS POSSIBLE WITHOUT THE USE OF PROPER SAFETY EQUIPMENT, SUCH AS A TIRE MOUNTING MACHINE WITH REGULATED AIR PRESSURE AND A CAGE TO PROTECT THE OPERATOR.

If you have any questions during the Bead Lock installation process, please contact ITP technical support.

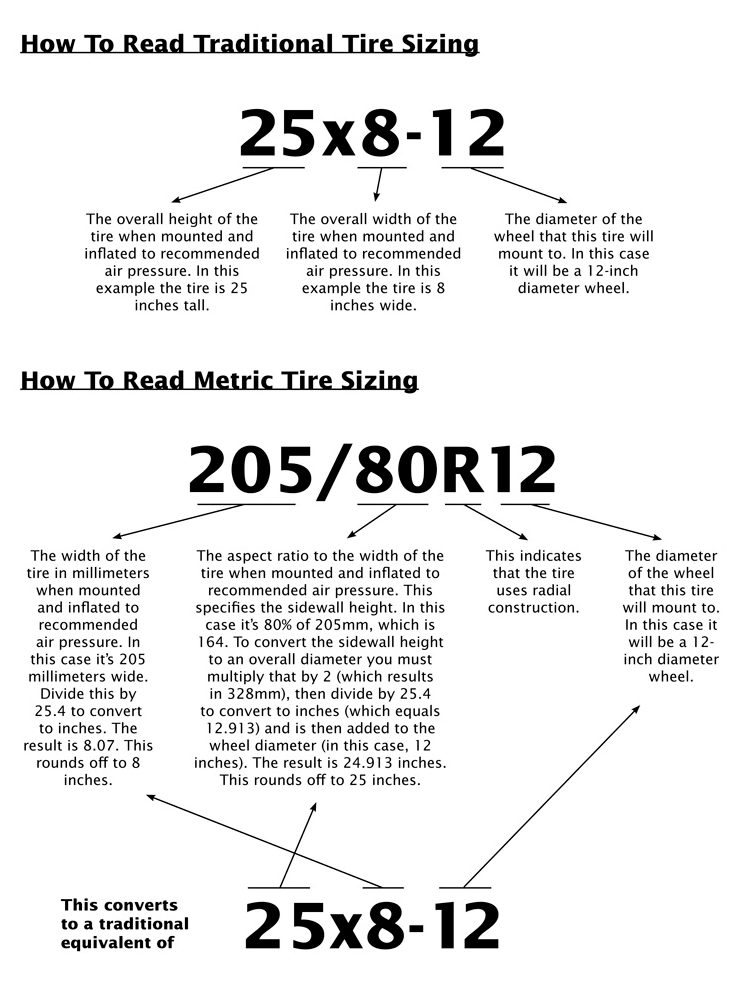

How To Read Traditional Tire Sizes

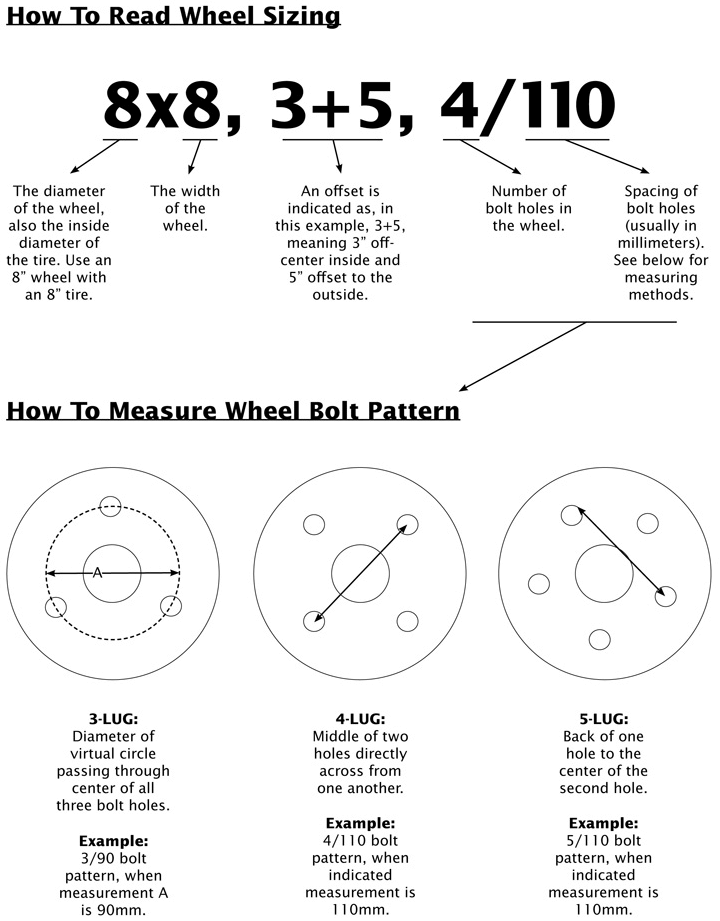

How To Read Wheel Sizing

Lug Torque Specification

We are often asked, “How much torque does ITP recommend to secure the lug nuts on my vehicle?” It is not possible for ITP to answer this question. We have no way of knowing what grade of stud the various manufacturers of vehicles are using. Therefore we must refer you to your vehicle’s owner’s manual for the recommended torque specifications for your lug nuts.

Tire Mount Safety Guidelines

WARNING: MOUNTING OF TIRES ON WHEELS CAN BE DANGEROUS IF DONE IMPROPERLY. ONLY TRAINED PERSONNEL, USING THE PROPER TOOLS, SAFETY EQUIPMENT, AND SAFETY PRECAUTIONS, SHOULD ATTEMPT TO MOUNT TIRE AND WHEEL ASSEMBLIES.

- Use only a clip-on style air chuck with a long extension hose, remote filler, and inflation gauge.

- Using a tire mounting lubricant, lube the tire and rim bead seat. Determine the tire’s maximum recommended tire inflation pressure.

- The tire and wheel must be located away from all personnel. Something solid, such as a block wall or a tire-mounting cage (see photo), must be between the tire/wheel assembly and the installer. THE TIRE/WHEEL ASSEMBLY MUST BE OUT OF “LINE OF SIGHT” DURING THE INFLATION PROCESS.

- Inflate the tire until you hear the beads seats snap, or until you reach the tire manufacturer’s maximum recommended tire pressure. NEVER EXCEED THE TIRE MANUFACTURER’S MAXIMUM RECOMMENDED TIRE INFLATION PRESSURE.

- If the tire beads do not seat, stop! Release all air from the tire/wheel assembly, and call your tire manufacturer or ITP for advice (909-390-1905).

- Once the tire bead is seated, disconnect the chuck, re-install the valve core, and inflate to proper operating pressure.

IT IS RECOMMENDED THAT TIRES BE INSTALLED IN A SAFETY CAGE SIMILAR TO THE ONE SHOWN IN THE ACCOMPANYING PHOTO. FAILURE TO FOLLOW RECOMMENDED PROCEDURES MAY VOID YOUR WARRANTY

How To Clean Wheels

- Probably the single biggest mistake when cleaning wheels is to use industrial cleaners, which can contain harsh abrasives. Mild soap and warm water is sufficient for routine cleaning.

- After cleaning chrome-plated wheels, you can apply a non-abrasive wax or cream to prevent surface corrosion. If you have clear-coated wheels, skip this step.

- Don’t let tire cleaners come in contact with your wheels, and try not to spray cold water on hot wheels.

- If you go to the car wash, don’t use steam cleaners or strong chemicals on your wheels.

- To brighten up your polished wheels (wheels without a clear coat finish) use a polishing cleaner.

- To sustain this great look, apply some wax to keep the weather out.